Want to know how to navigate the Victorian Web? Click here.

[In transcribing the following essay from The English Illustrated Magazine I have followed the invaluable, but here often very rough one found in the Hathi Trust online version. All illustrations come from the original article. — George P. Landow] .

HEN Charles Dickens was writing Hard Times the “Black Country,” as it was called, was one of the sights of England, and everybody whose business called him in that direction made a point of travelling on the Trent Valley line at night in order to enjoy the full effect of the blast furnaces — great towers of brick work, filled with burning coal or coke, melting limestone and fluid iron, from the top whereof issued a crest offlames visible from afar. There was something grim in these old towers perpetually vomiting flame and Stygian smoke and gases then suffered to run to waste, but now utilised as we shall presently see. What struck my juvenile mind with awe was the fact that these fiery monsters went on without cessation. They roared aloud and belched flames year out and year in, week-days and Sundays, morning, noon, and eventide, high days holidays and bonfire nights, as the people were wont to say in my own purely agricultural county. To the youthful mind much given to serious reading they formed a perfect illustration of “the fire that is not quenched.” I have since learned that at Sheffield the “chaps,” as the natives love to call themselves, take great delight in “a good smoke," that is, a solid cloud which plunges all who dwell in the busy town of three rivers into Cimmerian darkness. For a thick smoke shows that trade is good and furnace and forge in full blast. It is only when times are distinctly hard that furnaces are blown out or damped down, like the spirits of those who live by them. But the modern blast furnace keeps its secret better than its picturesque ancestor in Trent Valley, and as the train passes Landore and goes on to Swansea, the fire which shines out through rain and storm is only that of a regiment of coking ovens, the blast furnaces keeping their heat to themselves for excellent economic reasons.

Since the iron railings which stood till the other day around St. Paul’s Cathedral were made, English iron and steel-making has undergone many changes of method and locality. Just now it would seem as if wrought iron would in no very long time be superseded by steel, a fact which favours the makers of Barrow-in-Furness and South Wales, the former of whom have hematite ore on the spot, and the latter water-communication with Bilbao, whence the fine Spanish hematites may thus be cheaply carried. The railings just referred to were made in the cradle of the now enormous English iron industry, at Mayfield, the home of St. Dunstan in the Weald of Sussex, once forming part of the great forest of Anderida. It was at Mayfield that the Prince of Darkness came upon the Saint, who, happening to be at work, caught his visitor by the nose with a pair of hot pincers. The heat ought not to have been disagreeable, but it proved so to the baffled enemy, who made but - a hop step and a jump to Tunbridge Wells, where he plunged his nose into the spring and imparted to it its chalybeate qualities. All around Mayfield may be found the ponds marking the site of the ancient forges, which by degrees devoured the immense forest of oaks only just beginning in parts to recover itself. Furnaces fed with charcoal as these were make short work of a forest, as maybe seen here and there in Switzerland in the side-valleys off the great roads, where deserted mining villages show how the hills became denuded of trees. What would have happened in England if Dud Dudley had not shown people in Staffordshire how to smelt iron with “pit cole” is, not difficult to imagine. The iron trade would have settled like a blight upon the woodlands until they were swept clear of every twig. Luckily iron-making went to Staffordshire, where coal, iron, and limestone are handy to one another; Yorkshire, and more especially to Hallamshire where the steel-trade had early taken root. Later yet it has attained vast proportions in Scotland, and again later in Cleveland. South Wales has been occupied for a long time past with iron-making, the works at Cyfarthfa and at Dowlais being almost historical, the old water-wheels at Cyfarthfa having remained in use till very recently. Steel, however, is the form of iron towards which production in South Wales is most keenly directed, and at the Siemens Steel Works at Landore the newest devices for economising fuel and labour may be favourably studied.

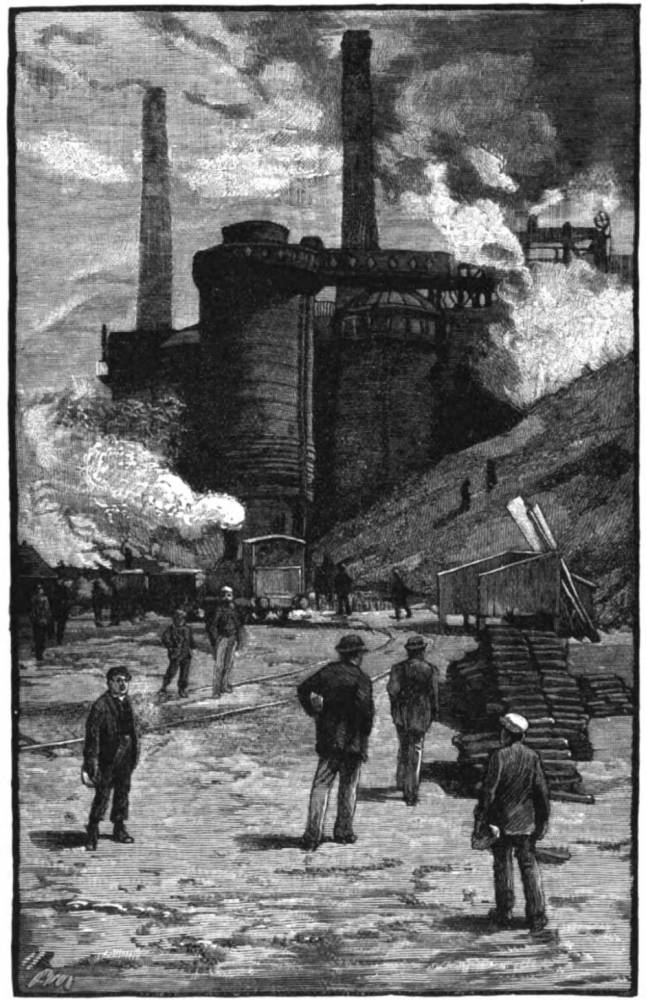

The Blast Furnace. Albert George Morrow (1863-1927).

Before attempting to describe in plain familiar language the latest scientific improvements to be seen at Landore, a few words may be spared concerning the blast furnace, that potent engine which has given part of Staffordshire its uninviting title of the Black Country, and has at Middleborough-on-Tees — which consisted some forty odd years ago of a solitary farmhouse — created a rich and populous town. Perhaps the clearest idea of its purpose is conveyed by the clay hand-furnace used by the natives of India in Marco Polo’s time as to-day in the manufacture of sword-blades of excellent quality. Marco imagined that the blades known as of Damascus or as of Persian make were made from ore called “ondanique” dug from a certain mountain. The ambassador of Kublai Khan had probably other weighty matters to occupy his mind, and just repeated what was said to him. As a matter of fact, however, the “wootz” or Indian steel is made of various carbonates of iron, requiring more treatment than the oxides such as the hematites. The carbonates require roasting to get rid of the carbonic acid before they are put into the furnace, and the Indian does all this carefully. Then he puts charcoal and ore into his little furnace with limestone, and applies the blast with a hand- or more generally foot-bellows. The result of this operation is metallic iron more or less impure according to circumstances. This is hammered and heated over and over again, and when thoroughly purified is placed in a crucible with various leaves and sticks of wood supposed to communicate some kind of virtue to the metal, and the crucible is placed on a fire and raised to a very high temperature. Thus decarbonised and purified and then recarbonised to the degree required, the Indian iron ore is made at vast expenditure of labour and time to yield fine steel. The result of all this hand-labour is perfect. What science and civilisation do is to produce fine steel much cheaper than is possible by this primitive method, and also in masses of immeasurably greater size, fit for the armour of a war ship or the breech pieces of mighty ordnance.

Brunel’s Viaduct, Landore. Albert George Morrow (1863-1927).

It is not altogether advantageous to make iron in too large pieces all at once, hence the “pigs” of commerce. If a certain man found a mountain of metallic iron in his field it is very questionable whether he could make much of it. If it were not close to a canal or railway the chances are that it would cost more to cut it and carry it than it would be worth. On such nice questions of carriage for arrival and means of delivery does the success of ironmaking depend. It is not so easy at the first glance to see why the manufacture of iron and steel should not be a continuous process without suffering loss of heat. But this has been tried in Styria, and “the practical man,” a very stubborn fellow, has decided against it. Apparently he cannot “sort” his metal and mix his qualities to his satisfaction till the “pigs” are cold. Thus the work of making iron and steel is entrusted to difierent hands. In the Indian workman's clay furnace with foot-bellows we have the remote ancestor of the costly structures we see to-day at Landore, Europe having got but little beyond Asia, till just of late. The small furnaces of the kind known as Catalan were long used for producing malleable iron, and blast—furnaces of slight elevation prevailed till a comparatively recent period as they do now, where charcoal is used as fuel, North America, excepted. Blast furnaces have been made higher and bigger until they are sometimes one hundred feet high. The Staffordshire furnaces now seem as trifling as a colliery chimney beside the great black towers of Landore and other modern works. In every variety of such furnace the blast, instead of being supplied by a pair of bellows, is forced by powerful machinery driven by steam. The “charge,” as it is called, consists of ore, limestone, and generally coke, but sometimes coal or charcoal, poured in at the top, in fresh layers as the lower ones are devoured by the tremendous fire, maintained by a constant blast of hot air. The invention of the hot blast by Neilson marks an epoch in the iron trade. When it is thought proper to run off the fluid metallic iron the blast furnace is “tapped,” as it is called.

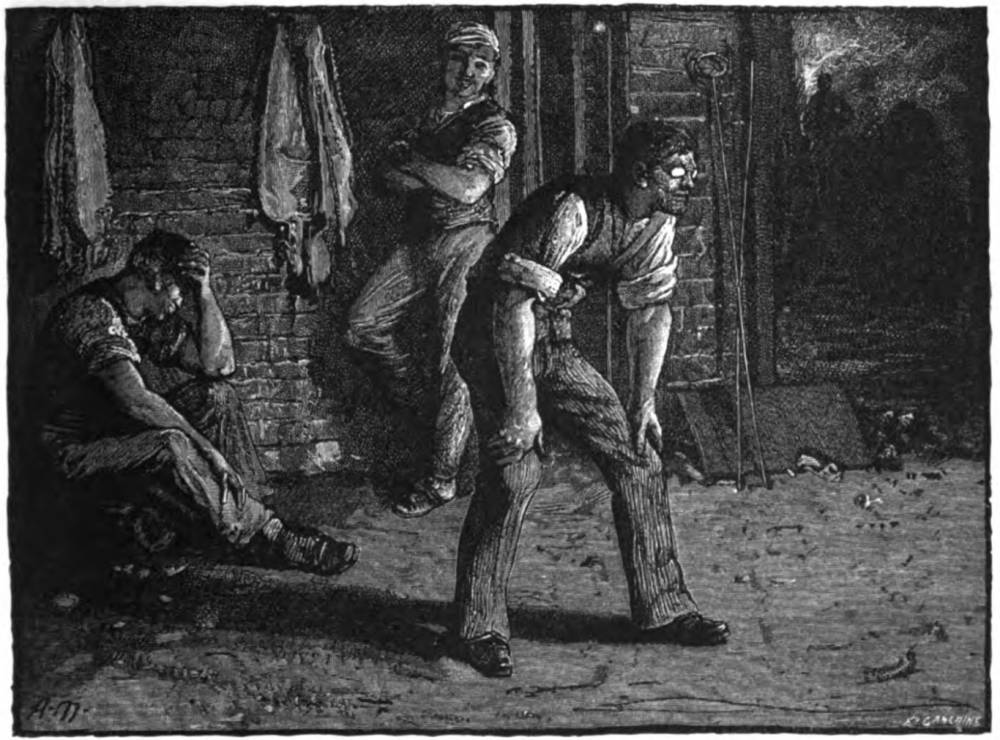

Tapping the Furnace by Albert Morrow. Click on image to enlarge it.

In former times for all kinds of steel—and still at Sheffield for the manufacture of the finest qualities of cast steel—the pig-iron obtained by “tapping” the blast furnace was reduced to the condition of “puddled bars,” that is made into pure soft iron by the application of the process of “puddling” invented by Cort, who, like many more genuine inventors, took very little by his invention. Swedish bars are perfectly refined iron smelted with charcoal and then “finished” into bars. Such costly material as this is best for the process known as cementation, or carburation. This process is effected by putting the Swedish bars into carefully prepared receptacles in a furnace and subjecting them to a great heat. The carbon in this process is supplied by finely powdered charcoal, mixed sometimes with lamp-black or other animal carbon, the vegetable carbon being found in the charcoal. This operation requires several days, and is not quite clearly lmderstood from a scientific point of view. The result, however, is what is called “blister steel” which, after subsequent rolling, hammering, and reheating becomes the fine steel of commerce. Bessemer steel again is made by blowing all the carbon out of fine pig-iron by a tremendous blast, and then adding just as much “spiegeleisen” or iron containing manganese as will supply the requisite proportion of carbon. This is as if one washed the original carbon out of pig-iron in order to be certain of the quantity one put back again.

The Siemens “open hearth” steel is yet another metal, in making which raw iron ore of the high quality of oxide such as hematite and scrap steel are used in the Siemens furnace to decarbonise melted hematite pig, which is afterwards treated with manganese and converted into steel. It would be an interesting inquiry to hunt out the origin of the application of manganese to iron to make it into steel. From stories I have heard of Huntzmann and of the unhappy inventor mentioned by Charles Dickens, it would seem that among the Indian secrets of venerable age that of applying manganese to purified iron to con ert it into steel was one. An Indian civil servant thought to make something of this in England, but his patents were disputed and he was ultimately killed off. Sir Henry Bessemer had made a previous fortune by a clever invention, and when he applied manganese to decarbonised iron he had forty thousand pounds to fight his enemies with. Consequently he made a million sterling — probably the largest profit secured by any inventor since the world began.

The Mumbles Light House. Albert George Morrow (1863-1927).

Landore is a short drive from Swansea, and is within a few miles of the Mumbles and the long waves of the Atlantic. Swansea is essentially a mineral seaport. It has copper works and zinc works, as well as tin plate works. There is a flavour of smelting all over Swansea. Sentimentalists have complained of the aspect of the grass in this peculiar locality; but sentiment has been completely answered by science and experience. There is, it must he confessed, a species of yellowness about the grass, and that the absence of trees is not less remarkable It is thus an arid drive to Landore. It is, however, asserted to be a healthy place. There is a local superstition that from the smelting of copper comes an antiseptic fume, which, while killing ofi grass, is useful in destroying any sign of typhoid. It is fatal, so pronounces science, to vegetable and the lower types of animal organisms. Be this as it may, the workpeople at Landore look healthy and vigorous as other iron-workers, which is not saying a great deal, for the heats and colds of iron-making appear to agree marvellously well with the human organism. But perhaps the wages earned by skilled forgemen, puddlers, and melters have as much to do with their healthy appearance as the profuse perspiration caused by their work.

Watching the Melting Ovens. Albert George Morrow (1863-1927).

The first objects visited are the coking ovens, seen last night through the storm. For a variety of reasons iron and steel makers like to make their own coke. Many go so far as to have their own coalpits, but the profit of this part of the scheme is great or small according to the market. During the coal famine of a dozen years ago those iron makers who raised their own coal gained enormously by their independence of the market, but since half a dozen years it has been perhaps cheaper to buy coking-coal than to run a colliery. Small coal is used for coke, and is made still smaller by a crushing machine which grinds the coal very fine indeed, with fearful noise and amid a storm of dust. In the great broad alley way between two rows of coking-ovens we find men busy in charging the furnaces with the pulverised coal, and in drawing the charges converted into huge grey rocks as massive and solid as it is in the nature of coke to be. This walk between the cokeovens is much of the nature of a valley of desolation, evil to the scent, and by no means grateful to the eyes, which, when clear of coke-dust, repose with pleasure upon hillocks of red hematite ore from the Bilbao mines. This rich oxide of iron requires none of the roasting necessary to carbonates, and is quite ready for the furnace like the masses of limestone just now being broken into convenient pieces. All this enormous bulk of material will be quickly devoured by the blast furnaces hard by. Instead of being built of brick alone, as in Staffordshire in the olden time, these huge edifices are cased with iron jackets. Looking at the furnace now, just about to receive an additional charge, it is seen to have two similar towers somewhat smaller in size standing close to it as its attendants or henchmen, and very important these auxiliaries are. Walking round the great central tower we are reminded that between its black hide of brick-lined iron — vast and round like the carapace of a prehistoric monster — and the actual edifice containing a column of molten iron, limestone, and incandescent coke, there is a space most important as checking the radiation of heat. The cost of the fuel employed in the smelting of iron is so great that every resource of ingenuity is exercised to reduce its consumption by economising the heat once created. Thus the gases generated in the blast furnace itself are no longer suffered to pour out at the top and waste themselves in empty air, but are carefully stored and employed to drive the blowing engines and to heat the blast itself in the supplementary towers devoted to that purpose. Above, below, and all around are large iron conduits, serving to carry heat from the spot where it is not wanted — that is, the top of the blast furnace — to the apparatus for heating and driving the blast of hot air forced into the base thereof through the tubes called “tuyeres,” which are only kept from melting by a jet of cold water which continuously pours upon them. Strange to say, it is not impossible to look into the blast furnace and see what is going on there. Cunning1y devised sighting tubes with coloured glasses allow the spectator to burning tears of metal dripping from the upper strata into the Phlegethon beneath.

Over a Gas-Producing Oven by Albert George Morrow (1863-1927).

Not a few steps must be mounted before the summit of the blast furnace is reached, and another aspect of the strange structure is won. Dancing upon an imaginary volcano is another thing from standing on the roof of a column of fire seventy feet or there abouts in height, and suggesting weird thoughts of Matthias and The Bells as well as uncanny stories of sudden disappearances in the rough old time of the Black Country. From beneath the cone which hangs by a chain from overhead, flames burst ever and anon beneath our feet. Around this upper opening of the blast furnace are trucks of ore, fuel, and lime stone for flux. With some caution we select the weather side of the roof, and presently the cone descends, and by leaving a space allows the torrent of material tilted on to it by the trucks to fall pell mell into the fiery tower, from which flames now shoot up. The charging of a blast furnace is a sight not easily forgotten, any more than the tapping of it if that operation be performed at night. The great blaze up of the inflammable gases, kept in by the cone at other times and conducted wither they can be made useful, is striking, as a bursting-out of pent up fires generally is.

The tapping of a blast furnace at night is a sight to see. During the afternoon we can see the casting-yard being arranged by a man who plans and plots out its area. This casting-yard is a kind of garden of an arid kind, attached to the blast furnace, and spreading for some considerable distance in front of it. In it grows nothing but sand and occasionally iron. It is prepared and plotted out with great care, as if for several series of miniature flower-beds connected by trim walks and avenues. All this work is done by a practised hand, and when it is over the hollow spaces blocked out in the sand mould are called collectively the “sow” and her “pigs.” When it is timetotap the blast furnace the clay stopping is knocked away, and the molten contents pour in an incandescent stream into the casting—yard. There are men stationed to knock away the little sand-barriers placed to direct the fiery flood, and presently the plan moulded by the work man is traced in flame. Not like a lightning flash, but slowly, and amid a thousand sparks the lurid mass bestows itself in the spaces of the odd kind of maze laid out by the caster. It is a beautiful sight, and enduring longer than could be imagined. Bit by bit each intricacy of the maze is revealed, but after a while the light sinks low, and the “pigs” of iron are left to grow cold in the semi-darkness.

This is the process, with very slight variations, of making raw iron, whatever its quality may be, whether fine hematite pig, called in the trade Bessemer, after the famous inventor, Scotch pig or Cleveland. Pig iron requires a great deal of working, like the Indian or the Catalan raw iron, before it is fit for use. When cold, samples are broken off the pigs to discover by the fracture whether the quality can be depended upon, and they are then re-melted for casting, puddled into Wrought iron, or made into steel by the Bessemer or the Siemens process. The former method has had the eifect of revolutionising the iron trade and increasing the production of steel five hundred fold. At Dowlais and at Rhymney, as at Sheffield, there are “converters” for making Bessemer steel out of the pigs of raw hematite. It is a curiously beautiful process, perhaps the most strikingly beautiful on a large scale in the working of metals. A small tower called a cupola is the furnace used for melting the pigs selected for conversion. When the molten iron has been heated to a high temperature it flows in a luminous white river into the receptacle known as the “converter,” in which the transmutation of metal actually takes place. This converter is an enormous vessel, like a Brobdingnagian decanter, moving its vast gullet up or down on a pair of “ears” or elbows, so that it can be tilted at any moment to the angle required. It is made of sheet iron, and lined with fire-brick or some other silicious material capable of resisting fire. In some respects the converter may be considered as a handy blast furnace, for it is furnished with numerous “tuyeres” for administering a terrific blast. It is very pretty to see the converter at work. While the charge, of some four or five tons, of melted pig iron is being run in at a red heat, it bows in one direction, and when the steel is made in another. What occurs in the converter is the complete washing of carbon out from the iron and the addition of just as much as will convert it into steel. This washing-out, or in a harder word, decarburisation, can be effected in two ways, by the system of Bessemer and that of Siemens. To continue with the former, the molten metal in the converter is subjected to a blast raising it to a temperature which, before the time of Bessemer, Was supposed to be impossible. Soon after the blast is turned on a shower of sparks issues from the gullet of the decanter. The colour of the changing flames and sparks, beautiful as the bouquet of a cunning pyrotechnist, reveals the changes in the composition of the iron until the carbon is entirely expelled. This charming experiment of practical chemistry on a large scale displays beautiful changes from yellow to violet when watched through the spectroscope, which tells exactly when the iron is thoroughly quit of carbon. Then a charge of manganiferous iron is added, the lip of the great decanter is lowered, and the incandescent draught poured into a ladle moved by strange hidden force as by the arms of captive giants. This ladle moves around a casting pit and pours into the already pre pared moulds the iron, now converted into steel, of such strength, density, and quality as may be required.

The Siemens process pursued at Landore differs in some essential particulars from that of Bessemer. The pig iron which requires a high temperature for proper cleansing from carbon is not subjected to a blast as in the Bessemer converters, but is boiled, absolutely boiled, at an astounding temperature in the Siemens gas furnaces, together with raw ore and scrap steel. The condition of the metal when it is at boiling point can be easily judged through a pair of blue spectacles. It is not possible, even for eagles, to look upon it with the naked eye. Confessedly it was not a new idea on the part of the late Sir William Siemens to devise a method of cleansing iron from carbon by means of boiling it at an enormous temperature and mixing with it native ore. But it was nevertheless a question of temperature, and it was the gas furnace, supplied on the spot with material, which solved the problem. With tremendous temperature hematite pig will undoubtedly give off its carbon to the iron oxide introduced in the shape of raw ore. This is, told simply, the rationale of the Siemens process, a question of heat and of the introduction of oxygen to absorb carbon. Through the blue spectacles it is easy to see a silver sea. The furnace, holding a charge of two or three tons of melted pig, contains nine inches deep of seething iron. On its surface, when the door of the furnace is opened, may be seen little wavelets and ripples like those seen under a light breeze at summer sunrise. It is a little lake of molten metal with more than its ordinary fluidity. As a rule molten iron and other metals have a peculiarly greasy or oily character, but the high temperature of the Siemens furnace seems to make the metal more fluid and to increase its vivacity, so that it seems to sparkle when seen through the eyeprotecting medium. To the purified metal is added spiegelcisen sufficient to convert it into steel, the furnace is tapped, the huge ladle called to work, and the iron, now converted into steel, is poured into ingot moulds.

Sometimes, if intended to be sold as ingot steel, it is allowed to become quite cold, and is then shipped by the canal hard by to the purchasers. In other cases it is made at once into bar, sheet, or angle steel. It is considered advisable to lose caloric in letting the pig iron cool on account of the advantage of sorting the metal, but as little as possible is sacrificed during subsequent operations at the forge or rolling mills. It is a pretty sight to see ship-plates 0or plates for bridges rolled. Let us look for an instant at the “three-high” rolls engaged in rolling a plate for the Forth bridge. A little detachment of men is laid on to deal with a plate weighing some two tons and two hundredweight. The great mass of steel is being raised to the heat necessary for rolling in a furnace in the immense building devoted at Landore to rolling and hammering purposes. At the proper moment the furnace is opened and the luminous mass is dragged from its burning bed on to a light, but sufficiently strong, truck and pushed quickly towards the rolling mills. An ingot or “bloom” of the great weight specified is not easy to move, and it is amusing to see the skill with which it is dealt with. Wheeled at a white heat up to the “rolls,” the mass is at first as it were reluctantly accepted, and passes into their jaws with some difficulty. Then it becomes by degrees flatter and flatter until it seems that it may become a. plate Backwards and forwards, spurting out flames as the jaws of the rolling mill close upon it, the great mass of incandescent steel is kneaded as if it were dough, and flattened out to the required size. As the fiery sheet pours out of the rolls boys run beside it with brooms soaked in water to wash off the oxidised skin of the metal, and thus leave a clean surface. While this is going on at one set of rolls, others are turning out plates and girders, angles and rods, and the iron floor on which we stand becomes so hot that we are glad to move into a pool of water to cool our burning soles. One by one the great plates are rolled and laid out on the floor. In the course of rolling they have become stretched a little at the sides, so that they have the look, as they lie red-hot on the ground, of the skins of mighty beasts recently torn from them and flung down by the hunters. Scarlet and crimson in every shade they are allowed to cool to a deep grey before they are cut by a machine, which makes nothing of their weight and thickness, into the exact parallelograms required for the Forth bridge, and for ship-building purposes, after which they are stacked in heaps ready for delivery.

Related Material

Bibliography

Becker, Bernard H. “Iron and Steel Making in South Wales.” The English Illustrated Magazine. 2 (1884): 223-x. Hathi Trust version of a copy in the Pennsylvania State University Library. Web. 3 January 2021.

Last modified 5 January 2021