With thanks to: Chris Cox of Craven Dunnill Jackfield Ltd.; Lesley Durbin of Jackfield Conservation Studio; Phil Gilbank for information and his talk about the porch; and Adam Hickey, Pinnacle Conservation, York. You may use the images without prior permission for any scholarly or educational purpose as long as you (1) credit the photographer or source and (2) link your document to this URL in a web document or to the Victorian Web in a print document. [Click on the images to enlarge them.]

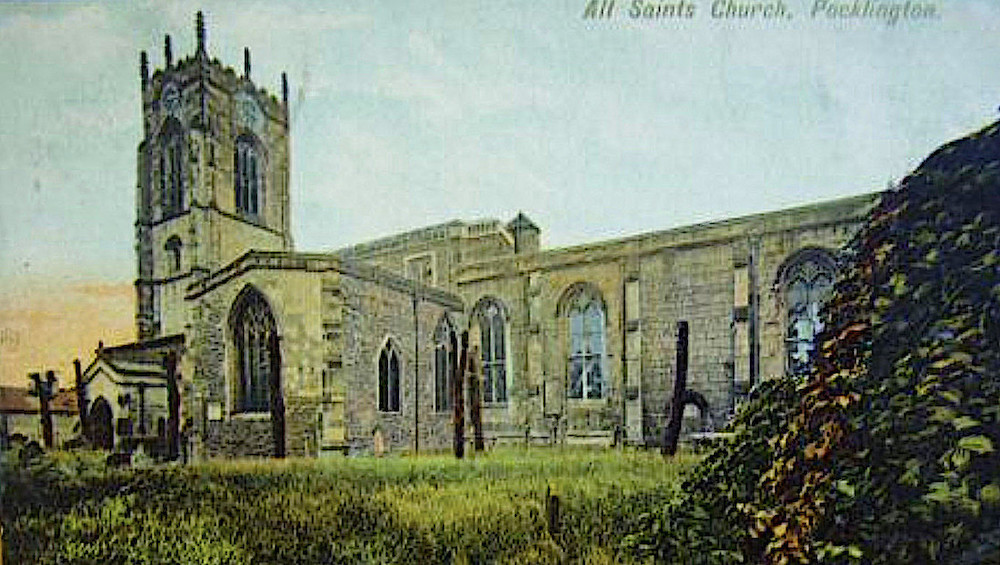

All Saints, Pocklington, an old postcard c. 1905 showing the church (on the south side, with the porch), reproduced by kind permission of Pocklington and District Local History Group.

A new porch at All Saints' church, Pocklington, was dedicated in May 1885 after the previous porch had been blown down in a gale (it had had no windows to relieve the pressure, but must have been in a fragile state). Some stonework could be reused, but the tiled floor was brand new and in the latest fashion. The tiles were made by a branch of the Minton family business, the Campbell Tile Company (Pearson 14-5). This company was associated with Colin Minton Campbell, and from 1875 it had used the name Campbell Brick and Tile Co. Tiles by this company are not very common.

At nearby Barmby Moor, the vicar had married a daughter of Herbert Minton, and that church has Minton tiles in its nave and chancel; their son Robert Minton Taylor also went into the clay business, sometimes working with Colin Minton Campbell. Robert eventually emigrated to America, as numerous East Yorkshire brick makers did, and fed the building boom of the United States and Canada (Phil Gilbank pers. comm.).

Two photographs by Phil Gilbank. Left: The porch in 2021. The tile discussed here is seen at the front. Right: A focus on the floor.

Whereas churches in that period would normally locate the most elaborate tiles in the chancel, at Pocklington encaustic tiles in a variety of colours were laid in a complex design in the place where they would receive frequent wear. After well over a century of traffic through the porch, colours were being worn away by friction, while the tiles were breaking up in some places, due to a process described as "heave fracturing" in the substrate. It has been decided to restore the original design using as many of the old tiles as possible. Replacement tiles are being made by Craven Dunnill Jackfield Ltd. of Shropshire and will be set by Pinnacle Conservation Ltd. of York.

In early 2022, to raise a little money, broken old tiles were being offered in exchange for donations. While tiled floors are familiar enough, it is not often there is a chance to see all round and under a tile, and the one purchased and illustrated below, demonstrates several interesting points.

Left: Top of tile. Right: Side of tile. Photographs by the author.

This tile was part of a border against the stone step at the entrance of the porch. At the top of the image, the colour has not faded but has been worn away by thousands of feet, and it can be appreciated how thin the added layer of blue is. Blue streaks crossing the design are stains from some accidental event. The orange staining is perhaps iron oxide which has developed out of the clay due to continuous moisture, for these tiles were subject not only to foot tread but also to wet foot tread (Durbin, pers. comm.). When removing the tile from the substrate it fractured, and at the bottom of the image, it can be seen that the decorated surface has easily split from the lower layers of the tile.

The tile is a sandwich with a red "filling" between the two layers of light yellow 'bread'; the sandwich is about 18mm (3/4") thick. The red clay is scattered with small white fragments of "grog," that is, previously-fired clay that has been ground up. Grog is added to a fresh clay body to make it more stable when fired, in this case to help keep the tile flat. The creamy clay forms a smoother surface, and having much less iron that the red clay, is not so likely to stain any added colours. It is used on both sides of the red clay to balance the effect and ensure shrinkage is even.

Left: The underside of the tile. Right: Intentional indents, a key for the mortar among other purposes. Photographs by the author.

The yellow clay allows moulding the under-surface to key into mortar or another medium that will firmly attach the tile to the floor. The underside of this tile shows part of the maker's imprint: "The Campbell Tile Coy."; then the company's trade mark which is a compass star with N, S, E and W, and then the location of the factory, "Stoke-upon-Trent". The word "tile" appears offset to the right: this is because the company was originally called The Campbell Brick & Tile Company and when they stopped making bricks, the word "brick" and the ampersand were removed from the back stamp, leaving the gap on the left. Earlier tiles show the full title. As well as the maker's imprint, there is a series of indents, these served to consolidate the layers, provided a key for the mortar and also allowed a little air into the body of the tile to assist in drying and firing (Cox, pers. comm.).

Bibliography

Pearson, Lynn. Tile Gazetteer: a guide to British tile and architectural ceramics locations. Richard Dennis, 2005.

Pocklington Church. PockingtonHistory.com Web. 12 July 2022.

Created 9 July 2022