Transcribed and formatted for the Victorian Web by Jacqueline Banerjee, who added the first illustration, from the Building News, and the captions.

Introduction

lay goods were first made at these works in the year 1858, and previous to this coal and ironstone mining was carried on. Burmantofts Pottery was quite unknown up to as recently as 1882. The Burmantofts Works, near Leeds, now the property of the Leeds Fire-clay Co. Ltd., were up to that time principally engaged in the production of salt-glazed sanitary pipes, fire-bricks and quarries, salt-glazed bricks, etc. Mr. R. Bond, the works manager, who has very kindly given me all the information in his power about these works, tells me that the year 1882 saw the first attempted production of pottery, and art pottery in its best sense.

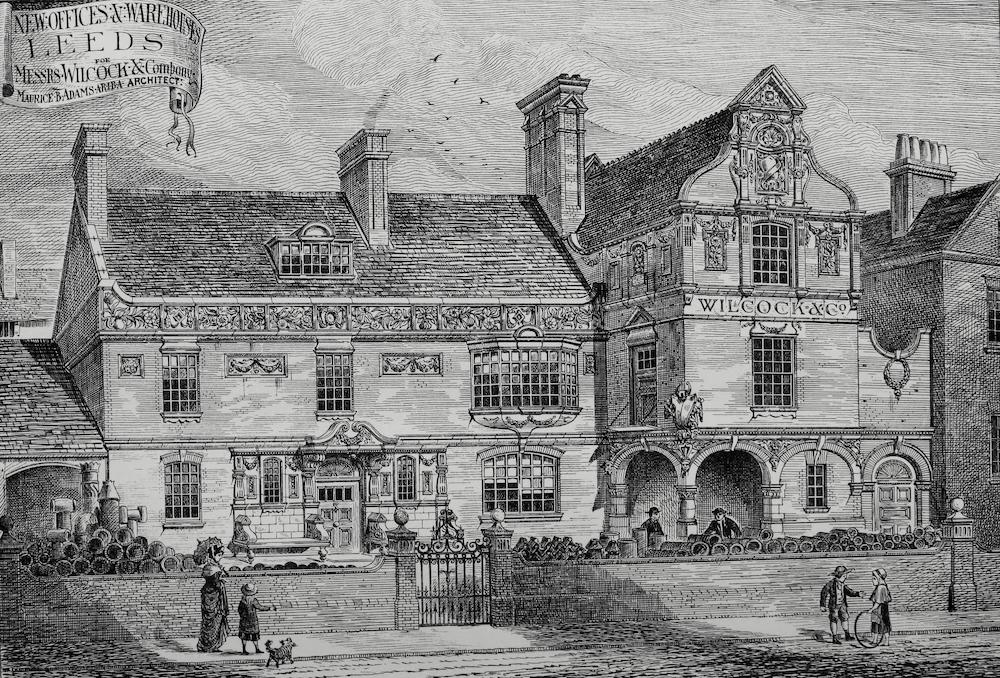

Wilcock & Co., New Offices and Warehouses Leeds, 1880. This was the company, in the Burmantofts district of Leeds, that originally produced the pottery and faience of that name. The panels on the façade of the new building, as featured in Building News, are of Burmantofts faience (see p. 628).

From the beginning the greatest care was exercised in order to ensure accuracy of work produced on the thrower's wheel, the outline of each article receiving most careful attention before it was permitted to go to the hands of the operator. The effect of this great care was soon evidenced by the demand from the important firms in the trade for this ware.

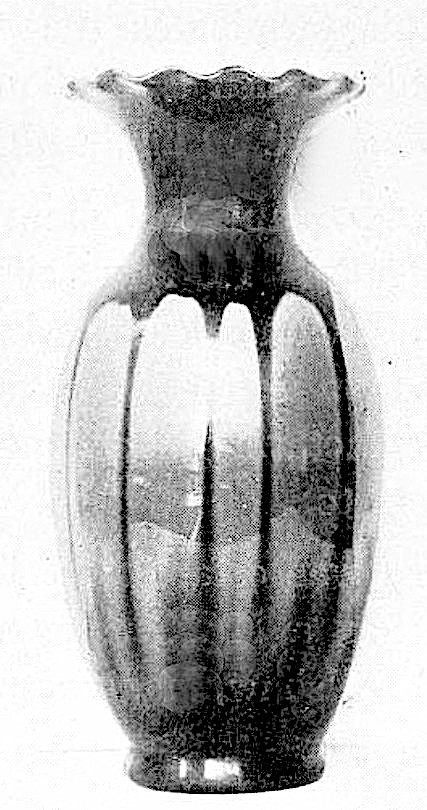

Burmantofts Pottery found its way into the best houses, and was called for from all parts of the world. Probably the outstanding feature from the artistic point of view was the purity of the three principal colours produced, viz.: Persian blue, orange yellow, and sang-de-Boeuf. In addition to these however, there [9/10] were many blendings of colours on plain pottery, and a portion of the plain pottery was also artistically treated in "slip" colours, flowers being the chief decoration. Later on, after much experiment, Anglo-Persian pottery was introduced, the distinguishing characteristic being its artistic colouring and effective design. In later years a popular demand was met by the production of modelled pottery treated in one or more colours of great richness of tone. It was a great blow to the artistic side of the productions of the city of Leeds that the manufacture had finally to be given up for want of financial success, but the pieces now in existence are much treasured by their fortunate possessors. The making of pottery was discontinued in August 1904. The pottery will all be found to be marked as per illustration, meaning "Burmantofts Faience."

The two illustrations accompanying Oxley's account. Left: The firm's pottery mark. Right: An example of Burmantofts "Splashed Ware" in the York Museum Collection.

The works are now employed in making terracotta Faience, which is a highly glazed and finished terra-cotta, made in all colours; ornamental tiles, and glazed bricks in all colours. A new kind of terra-cotta called "Marmo" was made in 1908, and in that year a building was erected in Coppergate, York, under Mr. Whincup, faced with this material.

Since the year 1880 great strides have been made by the successful adaptation of Faience to architectural work, and it is now largely used for permanent adornment of public buildings, principally of the Renaissance style.

The Burmantofts estate covers an area of about one hundred acres, some fifteen of which are occupied by workshops and kilns. Both the clay and the coal wherewith to bake it, are obtained on the spot, the former lies two feet thick, one hundred yards from the surface, under a fourteen inch seam of the Low Moor Better Bed coal, and covers about one hundred acres. It is sent up in rock-like blocks, requiring to be crushed and sifted by machinery, but is extremely plastic and tenacious and contracts but little in drying, will bear great heat, and when burnt preserves its hardness and exactness of form, solidity under pressure, and clearness of colour. A very large number of hands are employed here in the pits and various workshops, and in the studios a staff of [10-11] artists is constantly engaged. The whole of the designs as well as the articles made from them, are produced on the premises.

Related Materials

Bibliography

"New Offices and Warehouses, Leeds." Building News and Engineering Journal. Vol. 38 (Jan-June 1880). 25 May 1880. 628 (and lithogrpah following). Internet Archive, from a copy in the library of Illinois Industrial University, Champaign, Illinois. Web. 1 July 2024.

Oxley, Graham. Yorkshire Potteries, Pots and Potters. York: Coultas & Volans (associated with the Yorkshire Philosophical Society), 1916. Internet Archive, from a copy in the University of California Library, Los Angeles. Web. 1 July 2024.

Created 1 July 12024