Fat Boys, Tippers, Timbermen, Navvies, Muckshifters, and More

On public works, work began when the ganger blew a whistle and shouted 'Blow-up, blow-up'. It ended when he shouted 'Yo-ho, yo-ho'. Blow-up and yo-ho, the words, probably go back to canals, where a horn was sounded at blow-up, and lasted the distance.

Navvy-born boys began work when they were seven to nine years old, carrying blunted picks as big as themselves to the blacksmith's forge for re-sharpening. Ten and eleven year olds worked as fats or fat-boys — slithering about in mud under the wagons, greasing axles and wheel hubs. ('Fat' from the fat or grease they smeared on the wagons. A fat-boy was normally as lean as a long dog.)

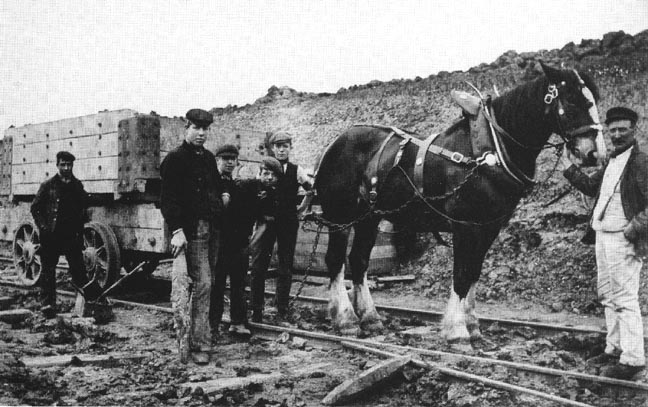

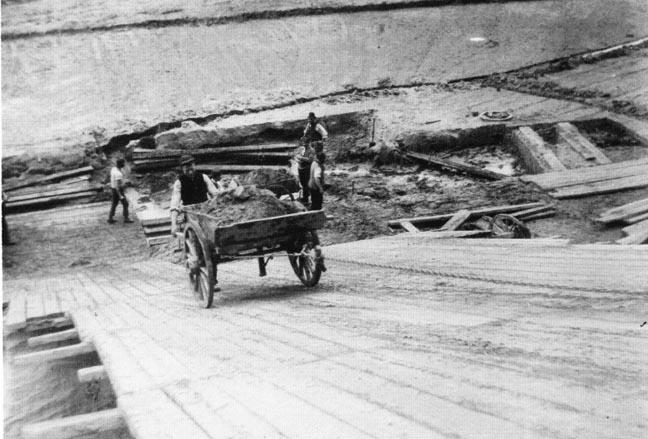

Nippers on the Great Central Railway, 1890s. Tipper and younger lad, 1890s Click on thumbnail for larger image.

Older nippers looked after the turn-outs, the points on the works railway where wagons and locos were turned in and out of the sidings or to and from the tiphead. Other boys of the same age were spraggers, poking wooden sprags between the spokes of free- running wagons to control their speed, particularly near the turn-outs.

Older boys — tippers — ran the wagons to the bankhead for tipping. Older than that they became full wagon-filling navvies around eighteen.

On top of that, adult navvies had a loose work-hierarchy of their own: miners, timbermen, navvies, muckshifters, and more.

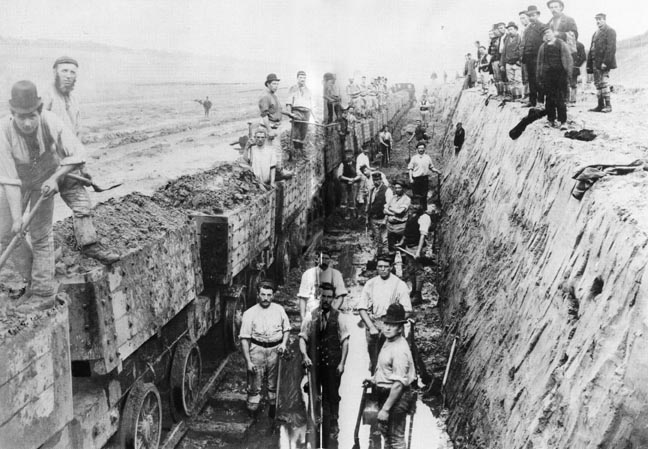

The classic navvy/muckshifter split was best seen among men working in cuttings. Navvies of the kind called getters or pickmen worked right at the muck-face, bringing it down into heaps suitable for shovelling away by other navvies called muckshifters, wagon-fillers, fitters, or runners-out. If they ran the spoil out in railway wagons, then wagon-filler and muckshifter were synonymous. Runners-out, more usually, were muckshifters who wheeled the [54/55] muck away in barrows, usually straight up the sides of the cutting on planks. Who did what was often a matter of chance — what job was unfilled when a man drifted in off the road. The best navvies could do, did do, all grades of work from muckshifter through timberman to tunnel tiger.

Wagon Fillers, 1890s. Click on thumbnail for larger image.

Tigers were tunnel miners and they were helped by other navvies called spannermen. Spannermen changed the drills, among other things. Some tigers, particularly in the early days, went straight on to public works from hard-rock mines (metal mines, like copper and lead, more frequently than coal). Others came up from the ranks of pure pick and shovel men. As between pickman and muckshifter (as between sea and foreshore) it wasn't always clear where tiger began and navvy ended, but generally speaking the tiger picked the places where he wanted the shot-holes to be drilled, and the navvy drilled them, working in turn as hammerman and drill-holder. The tiger then packed the holes with explosives, fused and fired them. Muckshifters ran the broken rock down to the shafts for hoisting to the spoil heaps. Most tigers stuck to their trade if they could (the pay was better for one thing) though some navvies seem to have switched from tiger-work, to pick-work, to muck-shifting without damaging their pride too much. Some men also tended to stick to other navvy sub-trades like concreting and timbering.

Concreting was a semi-skill on its own, calling for quick, accurate shovel-work when the cement/aggregate mix was at its proper semi-sloppy consistency. It became more important as more concrete was poured on public works, particularly after the turn of the twentieth century when whole dams (Kinlochleven, Seathwaite Tarn, Alwen) were made of it.

Timbermen worked the timber which shored up the sides of trenches and propped up the roofs of tunnels and > headings. Timbermen chose their timber, sawed it, nailed it, wedged it. They earned more than ordinary navvies but less than tigers. The extra pay bought the knowledge of where to wedge and what shape to wedge with. Once you'd emptied a space of muck, you didn't want to block it in again with baulks of timber and massive criss-crosses of splintery wood. On the other hand you didn't want the timberwork to be so light everything caved in again. A good navvy-timberman let in people, safely, as well as sunlight.

The British Navvy's Strength, Skill, and Endurance

Apart from living apart in their own communities, two things set navvies apart from labourers: extra strength, extra knowledge. Endurance was basic (it took a year to turn a flabby labourer into a man hard enough to work his shift in a muck-shovelling gang) but knowledge was almost as important. Knowing how to handle your body to begin with: once you bent your back at blowing up time you didn't straighten up till> yo-ho. On top of that you had to know how to handle matter, how to mine and timber, how to cope with the geology of what faced you, how best to pick, drill, blast, shovel all kinds of muck from rock to sand, clay to loam. Aggression and thick muscles got you there on their own, a few tricks got you there faster, and if you were paid by the piece that mattered.

What struck people most was the clock-like precision of wagon-filling. 'As fine a spectacle as any could witness is to see a cutting in full operation,' said one of Brassey's timekeepers, 'every man at his post, and every man with his shirt open, working in the heat of the day, the gangers looking about, and everything going like clock-work.'

Hard soil fell softly away under the shining shovels. Hard men moved smoothly like Wellington's soldiers at drill. Navvy gangs were like burrowing machines, their shovels like cutting blades, fuelled on beef and beer. 'These dissolute men exert themselves so violently in their work,' said Hekekyan Bey an Armenian trainee engineer, in 1829, 'that I have seem many powerful, muscular men with their blood oozing out of their eyes and nostrils.'

(The English navvy, who went abroad soon after the beginning of railway building, was a revelation to the foreigner. 'My God,' said the French, 'these English, how they work.' At first on the Paris-Le Havre railway the English navvy gave orders by stamping his foot, shouting 'damn' and pointing a finger like a pick blade at what he wanted done. A kind of Anglo-French lingua-franca soon grew up offering brief careers to bright young Savoyards who specialised in translating it. In France the English navvy was a creature to be gawped at for his bigness, uncouthness and wildness. They brought the navvy-sized iron tools and money-making barrows, discarding the puny wooden things the French worked with. Where the French ate sparingly of bread and fruit, the English swallowed heaps of bacon and beef).

A 'good hand' among early canal cutters could dig twelve cubic yards of easy earth a day — eighteen tons, or perhaps the space taken up by a large single-decker bus; a place big enough to set up house in. But that was easy compared to what came later. On the early railways a single navvy was expected to fill seven wagons a day. (In [56/57] fact they worked in pairs. Two were expected to fill a set, or train, of fourteen wagons between them). To do so each man lifted twenty tons over his head. Sometimes a pair of men filled sixteen wagons a day and even then the best of them were in the ale house by late afternoon. 'The men, who are the finest workmen in Europe,' said Hekekyan Bey, 'dig out twenty-five cubic yards of heavy clay each day — but their desire to run to the public houses and get drunk is so great that many of them perform their day's work in a few hours.'

In the 1870s Lincolnshire navvies in the Victoria Dock extension in London shifted twenty-five cubic yards of peat or eighteen yards of clay every eight-hour shift. On the Manchester Ship Canal, said John Ward, two men had to fill twelve four-yard wagons as part of a day's work — and that meant lifting twenty-four tons of muck eight feet, clear over your head. 'I defy any man to prove that any slaves in the whole history of the world were worked to the extent that English navvies are,' Ward added.

So I went to Stratford on Avon and went to work for Scott and Middleton on the branch line there. Filling wagons. Three and fourpence a day and you had to fill ten three-yard wagons. Two men to a gang and you finished when you'd filled them. But you had to buy your own shovel. Eighteenpence out of the office. Well, on all Jobs you had to buy your own tools.

Constructing Railways

A cutting, for a railway, began with a preliminary gash called a gullet, just wide enough for a single line of wagons. As the gullet widened to a full-width cutting an extra line of track was laid. Spoil was hauled away by gravity (if there was a down-slope) with only a brakesman riding each train — juddering, shaking, tossing, jolting his joints apart, his foot dancing off and on the brake.

Once the gullet and the cutting proper were opened, you faced a bare, flat, vertical face called, in fact, the face. You could either slowly hack the face back, slice by slice, from top to bottom, or you could undermine it at its foot and let gravity bring the lot tumbling down. (The column of undermined earth was called the 'lift'.) How men set about it was usually their concern. Often the head- contractor had little interest, other than in issuing a little self-righteous advice now and then. Usually, navvies went for the quick, bigger-money way.

Depending on the stiffness of the soil a face up to twelve feet high [57/58] is self-supporting. You began by 'holing' the bottom — cutting square holes in the base — but leaving pillars of earth holding up the rest of the mass. At the same time you cut a groove down the sides of the face. Sometimes a watch was set to warn of the ground cracking. The rest of the gang then began 'knocking the legs away' - chopping away the pillars holding up the face. Once the ground on top began moving, dirt was sometimes poured into the cracks which opened. If it trickled away a warning was shouted over the lip.

The skill was in making the right weight of muck fall the right way, and for that the height of the face was critical: too high, and it slumped down, shoving itself away at the foot, lumping up into a huge heap which then had to be expensively picked and shovelled away. Properly done the fall broke the muck into lumps ready for shovelling into wagons, which was then either dumped or, better still, used for embankments.

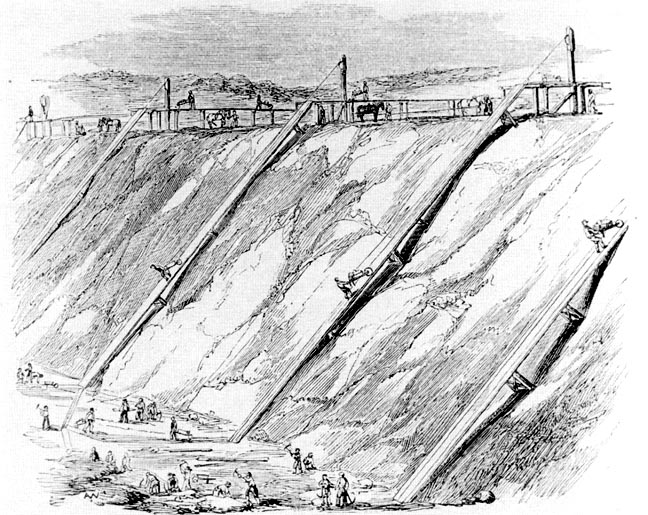

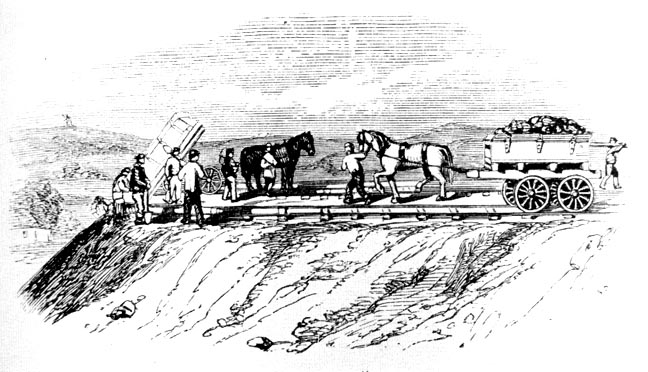

Barrow-runs half a century apart. Left: Tring Cutting, London-Birmingham (1830s) — right: the Manchester Ship Canal (1880s). Click on thumbnails for larger images.

As well as being shovelled into wagons at the bottom of the gullet, muck was also cleared by harrowing it up the sides of the cutting on narrow planks called barrow-runs. Full barrow and guiding navvy were hauled bodily skywards by horses; empty barrow and navvy then slithered down again under the influence of gravity and alcohol. Sometimes the horses on the topyard walked away at right angles to the cutting, sometimes they walked parallel to it, the rope twisted through a quarter circle by pulleys. Sometimes the barrow-runs ended in platforms next to a line of rails laid along the top of the cutting.

Robert Southey, poet laureate, described something similar at the Laggan cutting on the Caledonian Canal in 1819. 'The earth is moved by horses walking along the bench of the canal and drawing laden cartlers up one inclined plane, while the emptied ones, which are connected by a chain passing over pullies, are let down another.' The Caledonian is a deep ship canal and among the heaps of muck 'men appeared,' said Southey, 'in the proportion of emmets to an ant hill.'

They even had barrow runs on the Manchester Ship Canal, the most mechanised job of them all. Among the Whittaker steam excavators, the Priestman's grabs and Ruston steam navvies, men still scaled the sides of the cutting on planks, balanced by the weight of the barrows. They went up leaning backwards and came down crouching, their boots like brakes, their barrows like rudders. Some barrows were two-wheeled hand carts. More than the immense massed steam machinery it was the barrow runs that were the [58/59] wonder of the ship canal. On Bank Holidays visitors came in shoals to gawp at the men on the planks.

Moving the Muck

Muck from cuttings was taken, whenever it could be, to bridge nearby valleys with embankments, a trick learned early by canal engineers. Canal men tipped their muck, dry-shod, from hand barrows or horse-carts, though muck was also floated along flooded reaches and wheelbarrowed from the boats to the tiphead or bankhead, the place where it was shot off the leading edge of the embankment. Railway men trundled trains of tip-wagons to within a hundred yards of the bankhead where each was uncoupled for running down on its own.

The ground between the cutting, or borrow-pit, and the tiphead was called the lead. Railway lines laid on it were called teaming roads. Four were normal, six not uncommon and a thousand tons a day seems to have been teamed over them, on average.

One kind of tip-wagon had a bar sticking out the side to which a horse was hitched. Another kind had a coupling hook, linked by a light chain to the horse's swingle-tree. The tipper, an older lad, ran on the rail in front of the wagon, while his horse cantered outside him, clear of the rails. Near the bankhead the tipsman, or bankheadman, signalled him to slip his horse. The tipper snatched the chain off the wagon's hook and horse and lad got sharply out of the way. Except scores — thousands — of boys slipped on the rails and were killed or crippled, bouncing and bleeding, under the gravid wagons. It happened so often, some horses learned to undog themselves when their drivers tumbled under the wheels.

As the wagon free-wheeled past him, the tipsman knocked up its tail-board catch with his shovel. The wagon was stopped with a jolt by a barrier of earth and sleepers called bumpers or bumpsticks. The jerk flung the bed of wagon over, shooting spoil off the end of the bank. A good tipper got his speed just right and the wagon emptied itself. Otherwise, the tipsman, none too pleased, had to shovel out the residual muck. The tipsman also spread the spoil evenly on the slope.

Left: Tipping, London-Birmingham Railway, 1830s. Tipping, Great Central Railway, 1890s.< Click on thumbnails for larger images.

Pug or tank locos were later used for tipping. Each was handled by a driver and his rope-runner. The rope-runner (or ropey) was the fireman, shunter, guard, and the man who took the place of the tipper. With one hand he hung on to a rail on the front of the engine, with the other he held a long handled hook which coupled the loco to the muck wagon. The driver opened his valve and shunted towards the bankhead, watching the tipsman all the while. On the [59/60] tipsman's signal, the driver braked and the ropey jerked the hook off the coupling, and away free-wheeled the wagon into the bumpsticks. When tip-wagons were first used is unclear, though in 1805-6 Telford did have turn-up trucks at work on the Caledonian Canal, probably on the big embankments by the River Ness and the man-made peninsula in which Clachnaharry sea-locks were dug. One kind tipped sideways, but another which tipped backwards could have been freewheeled into an arrester barrier.

At Wolverton on the Birmingham line they tipped greasy, wet, dark clay straight on to turf for days, then weeks, then months. The embankment bulged at the bottom and spread out like a rubber bag of water. In the end they built the embankment backwards from the viaduct in the middle of the valley, carting material on a wooden bridge over the slipping area. (Not only did the Wolverton bank slip, it self-combusted. One bright morning the 'sulphuret of iron' mixed in it kindled spontaneously. Earth and sleepers blazed in the sunlight. 'Dang it,' said a rustic, 'they can't make this here railway, arter all, they've set fire of it to cheat the creditors.')

Canals, and some muck dams, were rendered watertight by puddled clay, an idea introduced by Brindley who probably learned how as a mill-wright. Clay and sand are chopped together with a little water to make a sloppy, non-porous mess which you lay in layers. (At first, the chopping was done by hand, but after the 1820s they used mechanical mixers called pug-mills.) On canals the layers were commonly ten inches deep, in dams, half a foot or less. Puddle gangs kneaded the stuff with spades, and trod and heeled it in specially heavy puddle-boots. (Heeled puddle had a rippled or stippled look.)

Navvies were invented because the> Industrial Revolution needed them to make canals, railways, and docks. Once invented, they stayed on to swab up some of the mess it made — in particular by damming and piping clear water to sickly towns.

Sewers and Sanitation Reform

What could be done about sanitation began to be discovered before the problem itself was properly understood or defined. In 1829 James Simpson, in Chelsea, showed you could purify dangerously infested water, by filtering it through sand, a quarter of a century before it was known that cholera and dirty water go together. A year or so later a Nottinghamshire engineer called Thomas Hawksley argued for a 'constant water service' — every pipe from dam to tap should be filled with limpid water like an extension of the lake. [60/61]

In 1842 Chadwick — one of the first Poor Law commissioners and the person behind the convening of the 1846 Parliamentary Committee which looked at the navvy and the way he lived — published a> report describing what it was like to be poor in an island where the sky was half air, half water — it was like living in a drought in a desert: the poor stank from lack of water to wash in. Black rain dropped through the Manchester sky like ink. What was needed, Chadwick argued, was clean water and a clean water supply's observe, sewers. Sewers, at the time, were cloacal rivers. The rich had Bramah's patent water closets which flushed the bowel movements of the gentry into cess-pits in their own cellars from where night-soil men, once a year and at dead of night, carried them away. What were needed were proper sewers and sewage works and these, for the first time, were made possible by nineteenth century technology, vitrified pipes and Portland cement in particular. From the mid-1850s onwards, Joseph Bazalgette's navvies in London laid out a thousand miles of sewers, some of them as big as rivers.

Dams and Their Construction

Clear water came from behind dams in the hills. A dam is big when it's over fifty feet high and in Britain there are about five hundred and thirty of them (nobody seems to have counted the lesser ones, like the Nethermere of Lawrence's Sons and Lovers, which in fact is a canal reservoir). As well as an unknown number of the unknown number of lesser dams, navvies built around three hundred of the big ones: fifty of masonry or concrete, the rest of muck.

Muck dam making is an old and probably native English art. Apart from the watermills listed in Doomsday Book, some of which must have had dammed water, the Bishop of Winchester made the Itchen navigable in the 1190s by building a dam at Alresford where it still sits, now so old, its lake shrunk to a pond, people think it's a natural bit of landscape.

For a hundred years most muck dams were copies of the ones made by the canal engineers who either inherited the art or reinvented it when they found they had to keep topping up the permanent way. There was a canal lake, now a weedy pond, in the Frome valley alongside the Thames and Severn. From the 1790s there were: on the Peak Forest, the Todd Brook and Coombs dams; on the Huddersfield, those at Slaithwaite and Marsden; on the Leeds-Liverpool, two dams stacked one above the other at [6l/62] Foulridge, as well as another, three-sided and tank-like, at Barrowford. Until Lake Rudyard was dammed, the Trent and Mersey was watered by pit drainings from the Golden Hill colliery, a mine branching off the canal under Harecastle Hill. Knighton reservoir, on the Liverpool-Birmingham, lay half on leaky rock, half on clay. Telford tried curing its leakiness by scattering clay from boats through the water but in the end he had to drain it and puddle the bottom properly.

The Scots were probably the first people in the British Isles — after the Romans — to drink dammed water on a city-wide scale: Glasgow first of all with the Whinhill scheme (1796), and then Edinburgh which raised the Glencorse dam in the Pentlands in tli^ iSzos. Manchester followed in the '40s, eventually flooding most of the Etherow valley with seven dams, the biggest waterworks scheme of its day.

Under the 1863 Public Works (Manufacturing Districts) Act local authorities could borrow cheap money to buy a way out of the distress caused by the American Civil War. A lot of the half million which was lent went on dams. Some canals, as well, were helped by public funds to off-set unemployment after the Napoleonic War. Money from the Exchequer Bill Loan Commissioners went into the Gloucester and Berkeley, the Regent's, and the Portsmouth and Arundel.

Muck dams at first were rendered watertight by a wall of> puddle clay let deep into the earth, filling a trench sunk to impervious rock. Later, concrete — rather than clay — was more usual but however it was in-filled the trench was always called the gutter, the core, the gutter trench, or the core trench. (The Bude canal dam, built across the Tamar in 1805, seems to have a brick core.) Above ground, the puddle is sandwiched upwards between sloping banks of earth: the air-face and the water-face. The lower parts of the water-face, which are dry only in droughts or after heavy draw-offs, were generally covered with broken stones called beaching. Above this, the part of the water-face exposed to the wash of the lake was clad in stone or masonry pitching.

Big earth dams normally have one or more steps, called berms or benches, in the air-face. As on a railway bank, the slope of the dam is called the batter. The berms and batters of the air-face are grassed and nowadays are normally grazed by sheep. Coming up-valley a muck dam often looks disconcertingly like an up-turned meadow. Masonry dams should be less bulky than muck dams but Liverpool's big, black, Vrynwy is massively overbuilt. It weighs [62/63] half a million tons. Stone for the dam and water for hydraulic power came from adjacent side valleys. The hydraulic pond is choked now but the quarry is still a slate-grey gash in the mountain. The stone is a hard, dark, grey slate, difficult to quarry because the planes of cleavage are perpendicular neither to their bed nor to themselves. It was shattered with gunpowder, detonated electrically, and the exploded rock was then split into manageable boulders with plugs.

For the dam's hearting, irregular rocks — called plums or Cyclopean Rubble — with the sharp end knocked off were bedded in cement-mortar and beaten in with wooden mauls. Smaller rocks were bedded in the spaces between the big ones. What spaces were left were then filled with concrete, rammed in tight with swords. The mortar itself was made from local sand mixed with pulverised rock and Portland cement. It was said its strength would grow with age. It was mixed in mechanical mixers, first dry, then sprayed with water, poured into iron tubs and run down to the dam. Every joint was packed with dry cement-mortar, tamped home until it showed wet.

Where water now stands was once the flat, boggy bed of an old lake below the Berwyn Mountains, looking into England. Vyrnwy was then remote and ghost-ridden. One particularly troublesome ghost was locked in a quill and imprisoned under a rock in the Vyrnwy River. When the time came to dig the gutter trench, the Welsh labourers shied away from the rock and refused to touch it. English and Irish navvies shattered it with gunpowder. Squatting in the smoke and rubble was a toad or frog, rubbing the sleep of ages from its eyes. The ganger shooed it away.

Vyrnwy, in its day a quantum jump, was quickly followed by other very big masonry dams: Thirlmere, Elan, Derwent. In fact there are two masonry dams, Howden and Derwent, in Derwentdale in Derbyshire, and no less than four across the Elan in Radnorshire. In Welsh the Elan dams are Gab an Goch, Gareg-ddu, Pen y Gareg, Craig Goch, which in English mean Red Cabin, Black Stone, Top of the Stone, Red Rock. Gareg-ddu is normally [63/64] drowned — usually all you see is the road stepping across its crest on arches.

Between the dam and the town, water is normally carried in an aqueduct or pipe track. Water is fed into it through a valve shaft or, in older dams, a straining tower, so called because copper gauzes strained out the solids. Straining towers are often turretted and arrow-slitted like Walt Disney castles.

Tigers, Tunneling, and Explosives

Probably the first tunnel tigers were hard-rock metal miners from Derbyshire and Cornwall. Tunnelling practice itself both altered a lot and didn't change much. At the end as at the beginning some tunnels were still driven by candlelight and gunpowder. Until the seventeenth century most hard rock mining was done either by the hot or the cold method. Cold mining meant crashing a way through rock with iron and wood: hammers, drills, wedges. Hot mining meant cooking rock to red heat with wood fires and then suddenly chilling it with water to crack it. Whole landscapes were deforested to keep the pit fires burning.

Gunpowder was used in European guns in the early fourteenth century. Around 1430 its quality was improved by caking it with alcohol or urine and grinding it into grains in ball mills. Gunpowder was a mixture of saltpetre, sulphur and charcoal (which darkened it into 'black powder'). It was rare because saltpetre was rare. Saltpetre (potassium nitrate) is found naturally as a product of rotting nitrous matter on which it flowers or effloresces as crystals and from where saltpetremen collected it. 'They dig in dove cotes when the doves are nesting,' a House of Commons man complained of them in 1601, 'cast up making floors, when the malt be green, in bedchambers, in sick rooms, not even sparing women in childbed, yea even in God's house, the church.' Charles II ordered his loving subjects to save their urine in pots, with the stale of their beasts, for the gunpowder industry.

The artificial nitre bed, built of layers of dead animals and rotting flora steeped in blood and urine, was one way out of the gunpowder shortage. As a result gunpowder, once too precious for all but the military, became common enough for mining. It reached the copper mines of Derbyshire soon after 1670. Over the next century its use became commonplace — in time for tunnelling canals through hills. At first gunpowder seems to have been poured straight into bare holes in the rock and firmed down with brick dust and chippings. In the Wapping tunnel on the Liverpool-Manchester it was used in tin tubes, like bicycle pumps, but later it was more usually packed in [64/65] linen bags, often by women in the huts as a sort of cottage industry. (Given the navvy's liking for high-banked fires and heat, it's not surprising accidents were common. Any number of people were running around on public works with one eye out.)

Dynamite and gelignite were more explosive, if trickier, and gunpowder itself was sometimes used as a fuse to set them off. The gunpowder fuse was often lit from a burning blob of gelignite, which sputters harmlessly in air. (A rock ganger once absent-mindedly put his blob of gelignite, still alight, into his waistcoat pocket like a box of matches. It blew his shirt off.)

The irony of tunnelling is that what seemed a refinement introduced by the late canals and adopted by the early railways was later abandoned in favour of the method used on the first waterways. Tunnels were bored from both sides of the hill and - simultaneously — from both sides of a series of vertical shafts sunk in a line through the massif the tunnel was piercing. In early canal tunnels the full-sized bore was driven straightaway but from the i/Sos tunnels more and more often were made by enlarging a pilot heading which had already been carried clean through the hill.

In the 1870s Pinkerton's Curdwonh tunnel on the Birmingham-Fazeley seems to have been made at least in part by enlarging a pilot bore, and the Blisworth tunnel, begun in 1796 on the Grand Junction, was about to be abandoned because it was too wet when the engineer persuaded the company to let him carry on with a through-heading. This heading acted both as a drain and a mini-hole which irised out into the full-scale tunnel. From the early 1830s to the 1860s all railway tunnels in Britain were driven in this way and, ironically, the change back to the full-bore method began in the Netherton canal tunnel in the 1850s.

Short tunnels, tunnels under water, and tunnels under high mountains were driven differently. With them you drove short headings in the conventional way, but every now and then you began "break-ups": burrows slanting up from the heading to the height of the finished tunnel. A second or top heading was then driven and deepened and broadened into the shape and size of a tunnel, supported all the while by a tunnel shape of large logs, called bars, laid lengthwise along the line of the bore. The weight of the hill was carried by the bars which in turn rested on props and wooden floors, called cills, which slotted into the sides of the tunnel and which were lowered bit by bit as the thickness of muck between the top and bottom headings narrowed. In a way the tunnel was [65/66] draped over a tunnel of logs until it was safely egg-shaped and self-supporting inside its own brick lining. The Severn tunnel was driven by 'break-ups'; so was the Cowburn tunnel under a spur of the Peak in Derbyshire, and the Totley between the rivers Derwent and Sheaf.

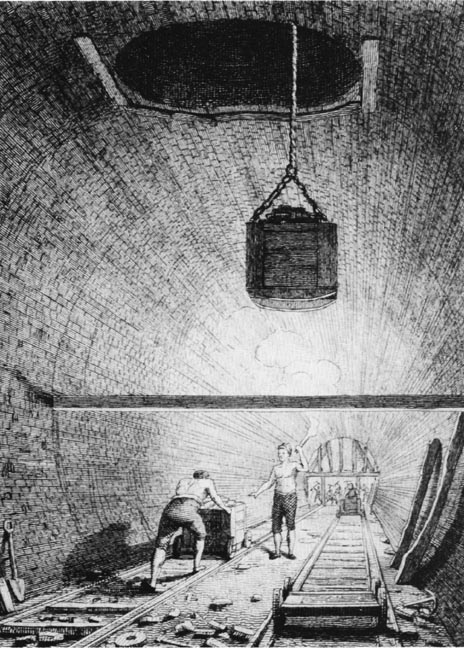

Islington Tunnel, Regent's Canal. Click on thumbnail for larger image.

In the Abbot's Cliff tunnel on the London-Dover a simple fan-shape of props standing on central pillars of chalk held up the roof, but more usually the space just emptied of rock/muck was immediately filled in again, almost as solidly, with wood: upright props, dense as young pine plantations; logs, called bars; planks. called wales; struts, dlls, ribs, frames, blocks, wedges, jacky pages brobs, sprag-props, side trees, head trees, slack-blocks, stretchers, sweeps. At the working face the miners excavated a hole for themselves which they left unsupported for as short a time as possible before pulling a roof of logs over their heads.

From 1825 (to 1843) Marc Brunel drove the first successful sub-Thames tunnel, using a tunnelling shield he invented himself (self-invented but inspired by the way the teredo worm chews holes in ships' timbers). With it he bored through ground as fluid as slurry. Often only a thin pie-crust of soft sickly mud separated the top of his tunnel from the bottom of the river. Bits of detritus — old shoe buckles, shovels, shards of china, (even live eels) — oozed through the river bed/tunnel roof and plopped on the tunnel floor. (In Januaryuary, 1828, the roof blew in. It began as a tumescent lump, a mud blister, which burst like a bomb. Sewage-coloured water exploded through the hole. Air, forced by the water, first made the gaslights flare and then blew them out.> Isambard Kingdom Brunel was literally washed out of the shaft, and danger, by a surge-wave.)

Thirty-six miners worked packed side by side in the shield in tiers of three, each in his own cell. Planks were screwed tight against the face. Each miner loosened one plank, scooped our four and a half inches of mud, then screwed the plank home again before loosening the next. The whole shield was screwed forward by jacks. The brickwork followed so closely it always touched the after end of the shield and only those four and half inches of unclad tunnel were ever unsupported at any one time.

The> second Thames tunnel, a subway no bigger than a heading, was bored near the Tower in only a few months of 1869 with a new type of shield. Men worked at both ends of a steel cylinder, cutting back the face at one end, feeding cast-iron liners into the tunnel at the other. Greathead, the resident engineer, later mechanised the [66/67] shield and used compressed air to keep water out of the workings. When he died in 1895, one of Greathead's shields was driving the sub-Thames road tunnel at Blackwall. By then the shield was so big whole gangs of men could work in it, miners at one end, muck-shifters shovelling spoil down chutes at the other. Compressed air kept the river out of the workings, although twice the air pressure blew holes in the roof at its thinnest part. As the air boiled away the falling pressure in the tunnel let more water in to recompress what atmosphere remained and exploded another blow-hole in the roof. And so on, in sequence, like a row of exploding land mines.

Getting the line of the tunnel straight was the first thing to do. In 1819 the Strood tunnel on the Thames and Medway canal (later turned into a railway) was probably the first to be aligned with a scientific instrument, an astronomer's transit telescope. Shafts were dug and two heavy plumb bobs dropped down them and steadied in tubs of water. The telescope was then lined up on their strings and the exact line of the tunnel calculated. Earlier, it's likely the engineer walked over the hill stretching a cord behind him and sighting along nagged beacons. In the summer of 1783 this is probably how Robert Whitworth aligned the Thames and Severn tunnel at Sapperton. Probably two plumb bobs were hung down Sapperton's shafts as well, though their strings were then lined up by eye and candle flame. Sea-compasses were used on the Liverpool-Manchester but candles were always the commonest way of keeping tunnels straight.

So, in London I was working in a gassoon in the Rotherhithe tunnel when I picked up with Dover Curly who said there was a lot of heading driving at Stoney Stratford, so we went.

We were driving this heading under the river for sewerage pipes. There was Scan Jones and some other mush driving from one side, and Dover Curly and me from the other. When we come to meet in the middle, under the river. Scan was eighteen inches out of centre with us. The ganger feller comes along. He says: 'Where's your centres?'

He says to us: 'You're all right.'

He went to Scan and dropped the line where Scan said his centre was. 'Where's your other line?' says the ganger.

Scan says: 'What other line? What do you want two lines for?'

Scan got into a hell of a row over that. They had to fill in one side. [67/68] You took your centres on two lines on plumb bobs, sighted on to candle.

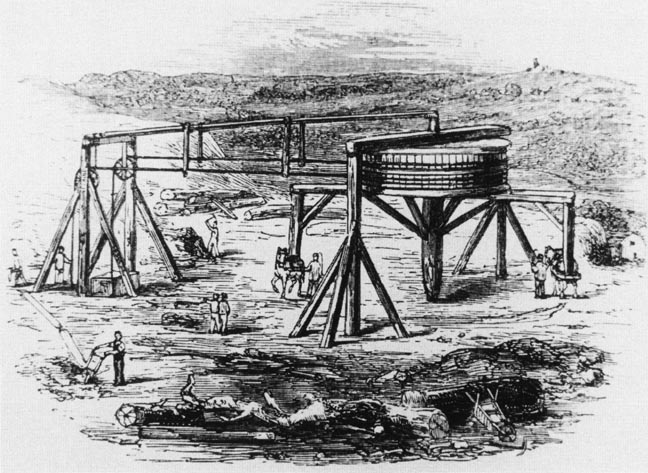

Shaft sinking was a navvy job. At Sapperton and probably elsewhere shafts were sunk like wells, walled as the hole was being dug. The bottom-most circle of masonry was built first, on top of a wooden curb, on top of the hill. As the earth was excavated beneath it the whole growing cylinder of masonry sank into the growing hole. The stone lining in fact was lowered ring by ring into the earth. The first-laid circle of masonry ended at the shaft bottom. It was a method called steining.

A Whim-gin — a horizontal horse-driven windlass. Click on thumbnail for larger image.

Man-powered jack-rolls or windlasses were the earliest winding gear over the shafts. Later, horse-driven whim-gins were copied from the coalfields. The horse was yoked to a horizontal drum around which the rope was wound with both ends hanging down the shaft. As the horse trod round and round, one end of the rope was lowered, the other end raised.

At first, as well, water was slopped out of tunnels with archimedean screws or else was spooned out with Brindley's spoons (a flap like a leather non-return valve opened as the spoon dipped into the water and closed as it was levered out. Water poured away through a channel in the handle). But as early as the 1760s, soon after navvying began, a crude home-made steam pump drained Brindley's Harecastle tunnel on the Trent and Mersey, and by the time the railways arrived engineers had steam pumps which could cope with almost anything. When the London-Birmingham was being bored through an undangerous and undistinguished- looking Northamptonshire hillside, at Kilsby, it ran into quicksand. The contractor took to his bed in despair and expired. In the end, thirteen steam pumps sucked away continually for a year and a half before the tunnel was dry enough for work to begin again.

Where things changed, they changed drastically. At Sapperton in the 1780s primitive all-wood railways carried all-wooden tubs with solid wooden wheels with wooden flanges on wooden rails. On day John Byng — Lord Torrington-to-be — took a cold, almost blind, ride into the tunnel straddling a sledge-cart pulled by two horses hitched nose to tail. (Only two cart-loads of muck were brought down with each blasting.) Away from the last of the smokey daylight the tunnel was lit only by Byng's candle and those of the men he passed. He went right to the working face through clinging gunpowder smoke. It was all a bit too enclosed even for him, an [68/69] agoraphobe who avoided straight coach roads if he could, and kept to winding lanes. 'My cart being reladen with stone, I was hoisted thereon, (feeling an inward desire of return), and had a worse journey back, as I could scarcely keep my seat.'

Ninety years later a steam engine pulled an endless wire rope in a mile long loop in the Severn tunnel: hookers-on clipped skips to it as it moved by them. They had electric lights and through-tunnel telephones and pumps big enough to suck up rivers.

In Wales the Severn tunnel opens on to a badly faulted coastal plain drained by a small river system, part River Nedern, part River Troggy. For a time the Nedern near its headwaters is bigger than the Nedern-Troggy on the plain: half way down it sinks into a patch of damp mud and rises again under the Roman walls of Caerwent. In Octoberober, 1879, the miners tapped into a fissure which tapped into the Troggy-Nedern and the whole subterranean water system. Wells and rivers dried up as water cascaded into the tunnel, siphoned up the shafts and lipped over their tops. Steam pumps drained the shafts and a diver in a primitive scuba-suit shut steel doors underground to isolate the flood. When they drained the tunnel they saw the cause, the Great Spring. Damming it took a year.

Next year the sea broke through the roof at a place called the Salmon Pool. Navvies plugged the pool's bottom (the tunnel's roof) with bagged clay. Then the Great Spring broke out again and this time, once the tunnel was drained, they led it into a sump, into which it still flows, and from where it is still pumped out. Then a high tide broke over the coastal meadows, flat as cow pats, on the Gwent shore and swamped the tunnel mouth. Men were floated out in boats.

Early Beginnings of Mechanisation

Mechanisation, of a kind, began early. In 1793 Charles Carne, a Cornishman, had a muck-shifting machine at work on the Hereford and Gloucester canal, where it was putting navvies out of work. (They seem to have resisted. 'The cutting across the Ham,' noted the Committee at a meeting in the New Inn in Hereford, 'not being as yet so expeditiously executed as we expected, and as we are convinced it may arise principally from the ignorance of the men employ'd by Clark, who has contracted for the cutting, and their unwillingness to introduce a new mode of Work upon the Canal, we conceive it to be absolutely necessary that Mr Carne should immediately attend himself, and bring with him Ten or Twelve Men from Cornwall used to work the Machines.') [69/70] The Machine — a muck-carrier, not a digger — was, essentially, a spindly gantry and a whim-gin. The whim-gin pulled skips along the gantry and simultaneously lifted them clear of the spoil heap. Navvies filled the skips and the increased productivity came from getting rid of the runners-out. (William Morris was taken on specifically to 'fill the Boxes for the Machines' at one end of the Oxenhall tunnel, and in June the committee sacked 'Dyer and the Men employed under him in cutting for the Machine' for slacking.) In 1794 the Machine was improved with cogs.

In April 1794, the neighbouring Gloucester and Berkeley began building their own proto-type Machine to the designs of Charles Trye, a committeeman, though it seems never to have worked. Mr Carne, meanwhile, tendered for the Gloucester and Berkeley digging and puddling contract. Did he mean to use his Machine to make a killing?

Southey discovered several bits of steam machinery on the Caledonian Canal when his Scottish tour took him there in 1819. Sea-going ships already reached Fort Augustustus where massive iron lock gates, carried from Gainsborough in a single ship, lay on the lochside. A steam dredger deepened the channel between Fort Augustustus and Loch Ness, raking black matter through water, funnelling billowing black coal smoke through the air. The black matter was shot from a ladder of buckets into rowing barges fitted with hinged bottoms. When the trap doors dropped open and the spoil fell into Loch Ness the barges bobbed about like corked bottles. Steam pumps cleared water from the gravel in the lock beds.

Farther along, a channel through Loch Oich was being deepened by another dredger, Glengarry, built of oak from the woods on the lochside. She was powered by machinery designed by Bryan Donkin, the man who began the canning industry when he invented hermetically sealed cans for the Royal Navy.

In 1803 a beam engine winched railway trucks up an inclined plane from the bottom of the basin to a jetty at the London Dock: the very first use, perhaps, of steam-hauled wagons on public works. In 1801 the Directors of the West India Dock Company asked Rennie to try grinding mortar in a pug-mill using a power-drive from a beam engine. The beam slowly rocked on its pins, paused, the engine slowly hissed steam, but it ground mortar so well it was kept grinding away until the dock was ready. (Unlike the steam-powered pile-driver Rennie proposed but never used.)

By the mid-1820s the Norwich-Lowestoft Navigation Company [70/71] had a small array of steam engines clanking away in unison as they strove to turn Norwich into a sea-port by driving a ship-channel through what was then unbroken beach at Lowestoft. After sailing through the beach, ships would cross a specially deepened Lake Lothing into the Waveney, then through a ship canal into the Yare. The ship-channel through Lake Lothing was scooped out by a little steam dredger. At the same time the passage through the beach (which is now Lowestoft harbour) was kept dry by dual-purpose beam engines which ground mortar even as they lifted water. William Cole,> clerk of works, wrote a poem about it all:

Here plies the Dredger with its powerful wheel,

To scour the Lake and load the ready keel;Impelled in motion by the engine's force,

Whose heavy smoke to leeward takes its course;And near, a hardy set their stations take,

To form a coalition with the lake;Revolving screw-pumps with incessant whirl,

The rising water from these workmen hurl.With a distinct monotony of sound

By day and night the Engine keeps its round;Alternatively the sinking buckets fill,

Whilst briskly turns the little mortar mill;With nice precision works the ponderous beam,

Proving at once the mighty power of steam.

But mechanisation proper probably really began in the 1830s in North America where skilled navvy-like labour was scarce. When Brassey's Lancashire and Cheshire men reached the Grand Trunk Railroad in Canada they couldn't have coped without machines. In Britain Brassey used steam cranes for the first time in the 1850s, in London, lifting muck straight out of the Northern Mid-Level sewer into carts.

'Invention has revolutionised the whole industry within the last fifteen years,' John Ward wrote in 1888. 'It was thought that navvies, like compositors, were outside the magic circle of invention, but time has taught us a rude lesson.'

In 1907, Mrs Garnett looked back nearly thirty years to the Denshaw dam. 'I remember one sunshiny morning, watching at the Junction, from the road above twenty-five piecemen. It was a wonderful sight to see the great muscles on their shoulders and arms [70/71] rise and fall with the precision of machines, and the way that long bank disappeared! To note their bright, good tempered faces, and as they paused, to hear the ring of their cheerful voices.' (Navvies worked silently, save for a peculiar navvy-grunt at every stroke of shovel or pick.) 'The introduction of machinery, while lessening hand labour, has certainly deteriorated the navvies' physique. We seldom see such magnificent specimens of humanity as were common thirty years ago, now on Public Works.' The navvy's shrinking physique curiously haunted people throughout the century as though it were a national asset or a source of legitimate imperial pride to own big navvies. In 1873 young Lord Brassey, son of Contractor Brassey, went so far as to blame one named year as the cause of the navvy's downfall: 1846, the peak year of the railway mania, the year of the Lancaster and Carlisle, Caledonian, Trent Valley, North Staffs, and Eastern Union.

Labour was so badly needed lookouts were posted along likely roads to stop men on tramp and bribe them into the nearest beershop where they were induced to work on the lookout's section of track. Work went on round the clock. Men worked over a hundred and twenty hours a week. 'Excessively high wages, excessive work, excessive drink, indifferent lodgings caused great demoralisation and gave the death blow to the good old navvy already in decline. He died out a few years after this period.'

Except he didn't. Thirty years after Brassey mourned his passing, Mrs Garnett gloried in his strength at Lindley Wood and the Junction dam. Ward's worry that steam would put navvies out of work didn't materialise either. Public works grew in scale, needing more and more of them. The only difference was they now shared public works with many more trades, particularly black-gang men (black because they were coal-stained and oil-soaked) who looked after the new machinery. [72/73]

Last modified 21 April 2006